Q61F Fully Welded Ball Valve

manufacturer: Kaiweixi Valve Group Co., Ltd.

Eml: Yannie@kaiweixi.com

Tel: +86(577)67038872

Mob: +86 189 6779 6135(WeChat Same Account)

Overview

Q61F fully welded ball valve is a permanent cut-off valve with a valve body and pipeline connected by welding of the same material, without external flanges and bolt connection points. The valve body is formed by welding multiple forgings or steel plates through advanced technology, and the internal structure adopts floating or fixed ball structure and soft sealing valve seat such as polytetrafluoroethylene. This valve is designed for high temperature, high pressure, and harsh working conditions, and can be opened and closed by rotating the ball 90 degrees. It has extremely high structural strength and sealing integrity. Mainly used in urban gas backbone networks, long-distance oil and gas pipelines, regional heating systems, and other buried or important above ground pipelines that are not allowed to leak, as key cutoff equipment for the system.

product drawing

Q61F Fully Welded Ball Valve

Features

1. Fully welded leak free structure: The valve body is formed by integral welding without any detachable flange connections, fundamentally eliminating the risk of external leakage of the valve body, especially suitable for the transportation of flammable, explosive, and toxic media.

2. High strength and long life: The welded valve body structure is continuous, with uniform stress distribution, strong pressure bearing capacity, and resistance to pipeline stress deformation and seismic loads. The design life is usually consistent with the pipeline.

3. Direct burial and compact design: No need to build valve wells, can be directly buried underground, saving space and construction costs. The external structure is extremely compact, with only a short valve neck exposed to the ground for easy operation.

4. Extremely low maintenance requirements: The fully welded sealed structure does not require maintenance under normal working conditions and operates reliably. The valve stem usually adopts a dual seal and grease injection emergency seal design to further ensure long-term sealing.

5. High performance sealing and driving: The sealing pair can adapt to large pressure and temperature changes, and is often equipped with fire-resistant design. Reliable ground or remote operation can be achieved by extending the valve stem on the ground or directly connecting it to a fully welded actuator.

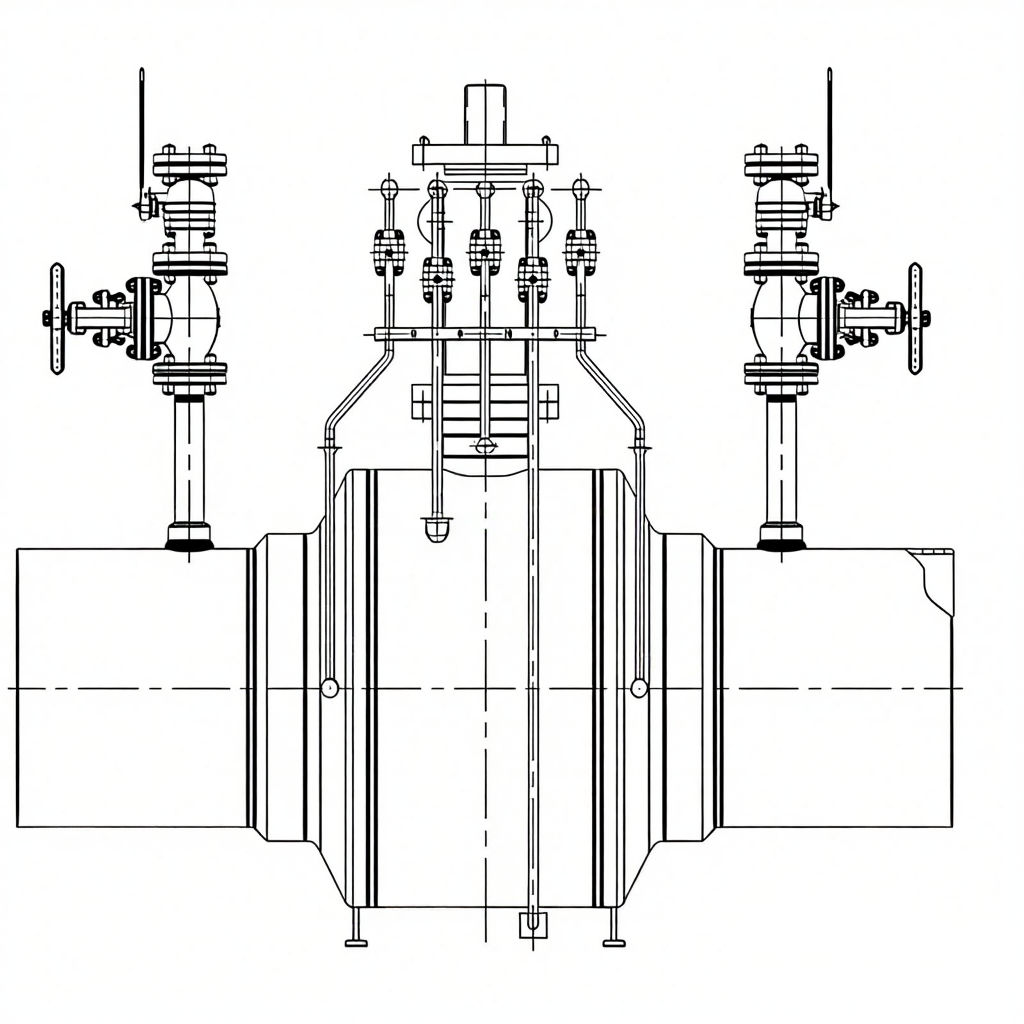

Structure

Q61F Fully Welded Ball Valve structural diagram

| NO. | Name | Material |

|---|---|---|

| 1 | Body | A105 |

| 2 | Ball | A105+ENP |

| 3 | Sealing Ring | PPL |

| 4 | Packing | Flexible Graphite |

| 5 | Stem | F6A |

| 6 | Bleeder Valve | A105-Hzn |

Technical parameter

| Item | Value | Unit |

|---|---|---|

| Nominal Pressure | 1.6/2.5/4 | MPa |

| Shell Test Pressure | 2.4/3.75/6 | MPa |

| Seal Test Pressure | 1.76/2.75/4.4 | MPa |

| Suitable Temperature | 300 | ℃ |

The materials of main parts

| DN | L(RF) | L(WE) | D1 | D2 | H1(Lever) | H1(Gear) | W(Lever) | W(Gear) |

|---|---|---|---|---|---|---|---|---|

| 15 | 150 | 210 | 27 | 48 | 64 | - | 129 | - |

| 20 | 160 | 230 | 34 | 60 | 76 | - | 159 | - |

| 25 | 180 | 230 | 42 | 76 | 85 | - | 159 | - |

| 32 | 200 | 260 | 48 | 89 | 95 | - | 245 | - |

| 40 | 230 | 300 | 60 | 89 | 124 | - | 245 | - |

| 50 | 270 | 300 | 76 | 114 | 162 | - | 30 | - |

| 65 | 280 | 300 | 89 | 140 | 175 | - | 320 | - |

| 80 | 300 | 325 | 114 | 168 | 192 | 169 | 450 | - |

| 100 | 350 | 325 | 141 | 203 | 205 | 183 | 450 | 230 |

| 125 | 350 | 350 | 168 | 219 | 225 | 203 | 450 | 230 |

| 150 | 400 | 400 | 219 | 273 | 245 | 224 | 1000 | 230 |

| 200 | 502 | 521 | 273 | 351 | 285 | 262 | 1000 | 320 |

| 250 | 568 | 560 | 325 | 426 | 348 | 322 | 1500 | 350 |

| 300 | 648 | 635 | 377 | 508 | - | 355 | - | 350 |