Damage process and phenomenon of ball valve sealing seat

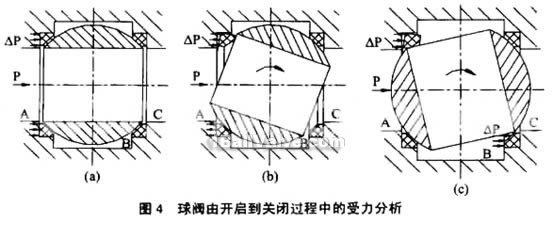

This paper analyses the damaged seal seat for floating ball ended and structure diagram is shown in figure 1. One seal seat materials with 350 degrees of styrene matchups.

The ball in high temperature and high pressure (6.0 MPa saturated steam) test process, found the seal seat damage, damaged seal seat as shown in figure 2. Through careful observation, discover the damage of the imported seal for medium, and the damage is the same, but the export seal seat intact. In order to determine the seal seat damage occurs in the valve open or closed during the process of ball valve, the valve in the experiment. First section and closed 6.0 MPa saturated steam l0 minutes, preheating, open valve, then check the sealing seat is damaged, Then in the valve opens, the 6.0 MPa saturated steam l0 minutes, preheating, shut off the ball, then check the sealing seat is damaged, the two test all inlet seal seat damage phenomenon. Because the ball float valve seal structure in medium pressure, under the action of sphere of displacement of the seal tightly on exports, which ensure the outlet seal, so the inlet of damage, sealing valve does not affect the sealing performance, has certain concealment. When multiple on-off movement.ball valve inlet, seal seat damage will be partial shear falls off phenomenon.

damage reason analysis of sealing seat

Based on the seal seat damage, and the consistency of the open and closed process will occur at the same site inlet seal seat damage to the valve open, so the process.

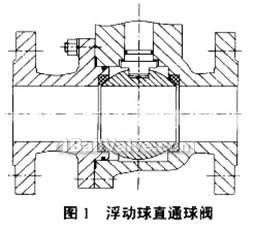

As shown in figure 3a shows that when the valve is in the closed position, sphere in the medium pressure, the pressure generated must tighten the displacement in exports and sealed by the export of sealing ball valves ensure sealing seat. But the inlet of the sphere seal seat back, because of its bottom sealing, reduce stress than small medium access to seal seat at the bottom, the medium pressure, the seal and the spheroid all contact, this wasn't damaged seal seat, When valves are open operation (see chart 3b), the inlet valve and A central lumen formed A port B will produce A differential pressure, flow, when the train P in contact with seat from the sphere, this part of the seat will lose support in the medium pressure, the effect of the bending deformation. When continue rotating sphere, seal seat edge bending part will be channel by bad and lose its sealing performance.

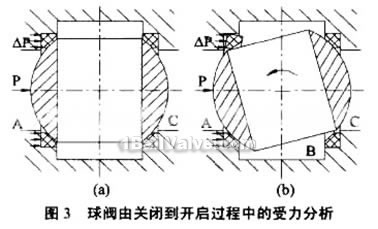

The ball too similar. Figure 4 shows, when valve is fully open, due to valve assembly pre-tightening force and nonmetallic seal seat of thermal expansion coefficient of expansion of non-metal (than metal coefficient of expansion of large, medium of channel) cannot enter ball valve B cavity, therefore channel and central ball there exists a cavity pressure B, but this train P seat sealing seal all contact with the ball, sealing seat won't happen deformation, When the ball when closing operation (see chart 4b), sphere channel and B cavity pressure balance of a process, the medium to B cavity, when flow in contact with seat from the sphere, this part of the seat in the medium pressure lose bearing, the effect of the bending deformation. This kind of deformation can occur in the upper left corner, can also occur in the lower right corner, the imported seal seat is damaged, because when closed ball to position, A figure 4c cavity and B cavity, B and C between between cavity pressure and will produce A train, A cavity and P cavity pressure difference between B to train the inlet valve P more serious, bending deformation and B and C cavity pressure difference between outlet seal seat will make the deformation repaired-not when continue rotating sphere, the inlet of the seal seat, the bending deformation part will be sphere channel, which crush edge outlet seal seat is not damage.