Damage resolution methods of high-temperature ball valve sealing seat

Through the analysis of the causes of the failure in the second quarter, know the inlet side sealing seat damage is due to A cavity and B cavity pressure difference exists, and therefore cause enables delta P as reduce A cavity and B cavity pressure difference between, can avoid to seal seat on opening and closing process occurs, the bending deformation and damaged, not changing the original floating ball through ball, on the basis of the two kinds of measures taken below:

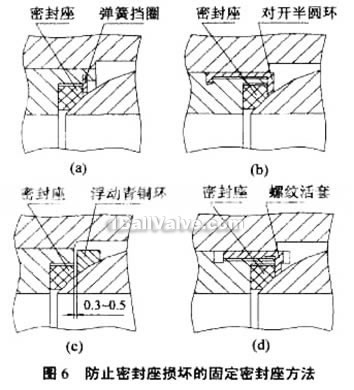

(1) process for open valve seal seat damage, adopted in seal seat 3xlmm six of the inner drive roof-floor trough (see chart 5). Due to the valve is closed, the pressure on the ball under the action of displacement, the seal tightly in export and import sealing seat at the bottom flabby condition, through the roof-floor groove can rapidly balance A and B cavity pressure cavity, open process, due to the increased medium pressure tank from A to B cavity flow of lumen area, thereby reducing the A cavity and B cavity pressure difference between train p, thereby eliminating the seal seat cause damage occurs, the bending deformation factors.

(2) process for close valve seal seat damage, taken in the sphere of drilling a hole 6mm φ roof-floor 5b (see chart). The discharge valve to open hole in A cavity, and B cavity, thus obtained connected close valves produced during the pressure differential train P disappear completely, eliminate the seal seat, the bending deformation occurs.

According to the above methods, the valve seal seat and sphere were improved, and the improvement of the ball after high temperature and high pressure test (6.0 MPa saturated steam). After repeated experiments, the original import sealing seat damage phenomenon, this is no proof of the original cause damage to the seal seat of analysis is correct and take measures is effective.

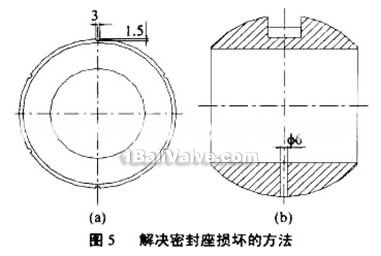

Finally introduces four by fixed ball valve seal seat sealing seat to solve the bending deformation damage, figure 6 four fixed seal structure of block diagram.